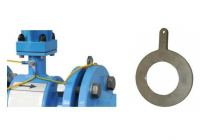

Carrier Ring Assembly

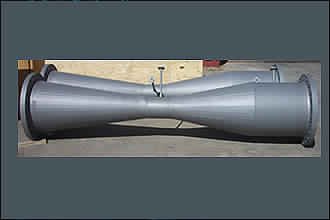

Carrier Rings are used in place of integral Orifice Plate closed coupled manifolds where the temperature are high, Also Carrier Rings are used for applications of large size flow measurements with Rotometers as Bypass Roameters. Its is Cost saving when used for large pipe diameters in stainless steel construction.

BENEFITS:

- Simplified Installation

- Accurate for line size leass than 2 “

- Cost Saving

CARRIER RINGS

- Diameter : As per PCD dimension of Flange Unions.

- Pressure Rating : 300,600,900,1500,2500 LBS As per requirement, Minimum thickness 37.5 mm

- Material :

- Forged Carbon Steel as per ASTM-A-105 fcr Fr I & II

- M.S. BAR SROCK

- S.S 304, 316, 316L Forged as per AISI standard

- IBR Alloy Steel, others on special request

- Corner Taps : 1/2″ NPT (F) – One tapping per carrier ring

COMPANION FLANGE

- Diameter : As per ANSI-B-15.5

- Pressure Rating : 300, 600, 900, 1500, 2500 LBS

- Material :

- Forged Carbon Steel as per ASTM-A-105 fcr Fr I & II

- 304, 316, 316L as per AISI Standard

- IBR, Alloy Steel, Other on special request

- Type : weld neck raised face / slip-on raised face

- Stud Material : ASTM A-193, Gr B7

- Nut Material : ASTM A-194 Class 2 H

- Gasket : As per application, asbestos, graphited asbestos & Others